OR: Is this going to spiral out of control like a record?

Have you been thinking about producing a catalog, manual or workbook? Does a spiral binding makes sense from a user’s standpoint because it’ll lay perfectly flat when it’s open? With spiral binding there’s no irritating tendency for the book to snap itself shut, no need to constantly have to find your place again. If this is the finishing method you want, no need for your mind to spin on how to correctly set up your job or feel like the process is going to spiral out of control!

When a job is going to spiral bind, a stack of individual sheets is drilled or punched along the spine side. Then a coil is inserted through the openings along the entire length. That’s it!

For the most part, you’ll set up your files as you would for a saddle- stitched or perfect bound book, with a couple of important differences.

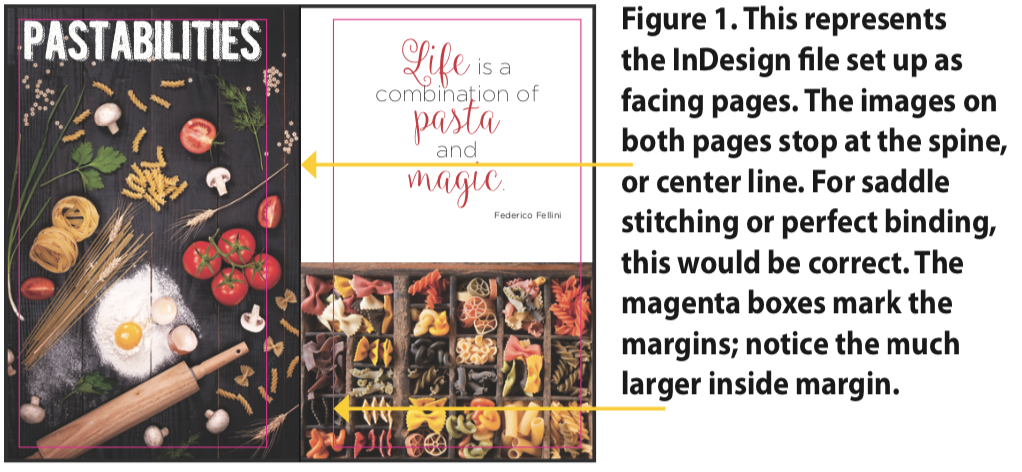

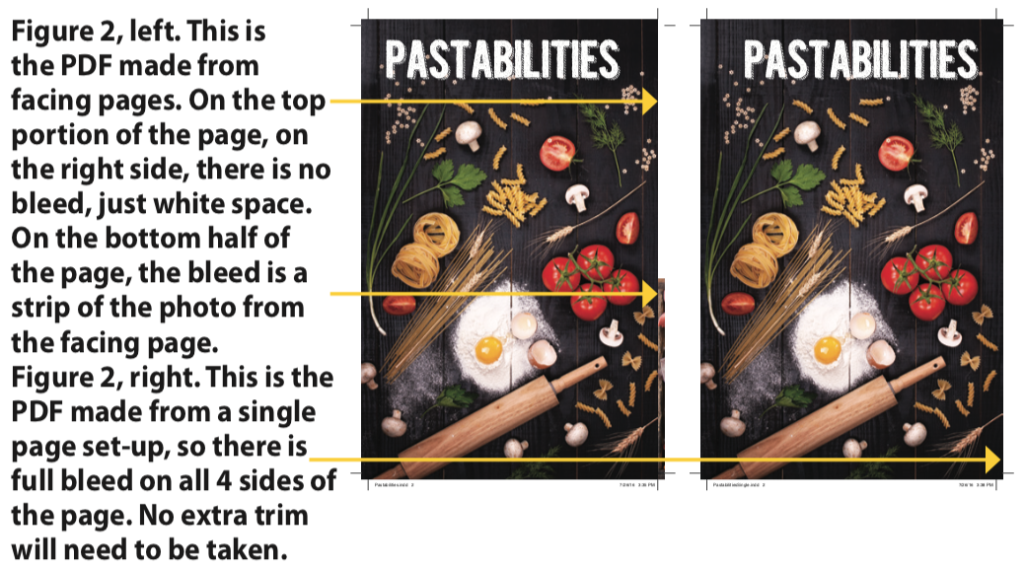

Remember the stack of sheets we mentioned? This accounts for the main difference in how you set up your document, compared to the set-up where other binding methods are used. For a spiral bound publication, you need to set up your document as single pages, not facing pages. Why? Because all 4 sides of your page need to trim, which means all 4 sides need to have bleeds.

If you set up your file as facing pages (See Figure 1) and your background stops on the gutter, the spine side of your pages won’t have bleed. Or the bleed will be 1/8 inch of the image from the spine side of the facing page. See Figure 2. Due to minor variations in printing and trimming, this could result in slivers of white paper or slivers of the image from the facing page being visible along the spiral edge. These inside edges won’t disappear down into the binding like they do with perfect bound pieces, so these variations won’t be hidden. Oftentimes the only way to correct this is to take a slightly larger trim on that side of the pages. Now your publication is a little smaller than you planned. Plus the margin on that side has been reduced, so the coils could end up too close to your text.

Speaking of the margin, this is another area that needs special treatment. Most of the time, .25 inch margin all the way around should be adequate. However, your inside (or spine side) margin should be set to at least .5 inches, and preferably to .625 inches.

When the holes are drilled or punched, they need to be far enough away from the edge to prevent the coils from tearing out. Different types of coils and wires will drill at different distances, but some will go in as far as .5 inches. This is why we recommend an inside margin of .625 inches to be sure that none of your text or important graphics will get drilled through.

If you have questions about setting up a job for spiral binding, please contact us!